Introduction

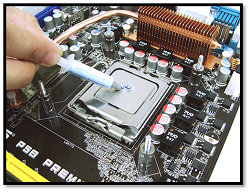

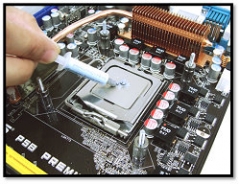

Whenever you install a heatsink on a CPU or a video card, you always have to apply thermal paste. It is very crucial to the performance of the heatsink. You could get a very high-end heatsink, and without thermal paste, it will fail to work in the way it was designed too.What is thermal paste and what does it do?

Thermal paste is a very high heat conductive paste that is used between two objects (usually a heatsink and a CPU/GPU) to get better heat conduction. It fills in all those microscopic imperfections on the heatsink and CPU/GPU that can trap air in them and cause a loss in the heatsink’s performance. Air is a very poor conductor of heat. Thermal Interface Materials (TIM) can be up to a 100 times greater conductor of heat than air.However, thermal paste is not near as good of a conductor as copper. Thus, too much thermal paste will hinder a heatsink’s ability to cool properly.

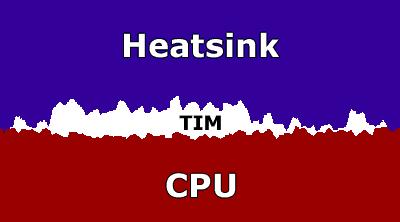

This is an exaggerated view of what these microscopic imperfections would look like. All the white area would represent the air pockets, and this is what the TIM would fill in. It wouldn't be such a gap like this, but this just an example to give you a rough idea of what it would look like.

If you could have a perfectly flat heatsink base, and CPU, you would not need thermal paste. But it is impossible to do so, and that’s why we need thermal paste.

Types of thermal paste

There are essentially three types of thermal pastes:- Metal based

- Ceramic based

- Silicon based

Ceramic-based TIM’s are also a popular solution that doesn’t perform quite as well as metal-based pastes, but the difference is minimal (1-3C). These consist of some form of thermally conductive material with lots of little ceramic particles. The advantage of ceramic-based pastes is that they do not conduct electricity.

Silicon-based TIM’s are usually what thermal pads that come on stock heatsinks are made of. These work well, but nowhere near to what other pastes will. Usually they come with cooling kits.

There are also thermal epoxies, these are basically the same thing as regular grease, but are actually used to permanently attach the heatsink. They are not recommended for most cases, but in some they are of course. One main example for a use of an epoxy is, attaching heatsinks to video memory. Most of the time you use thermal pads that don’t perform very well, so an alternative is thermal epoxy. But the disadvantage is, that most of the time you will not get the heatsinks off once they are put on.

What can be tried to get epoxied heatsinks off is to put the video card in the freezer before trying to remove the heatsink. The low temperature will make the epoxy brittle, so it goes off easier.